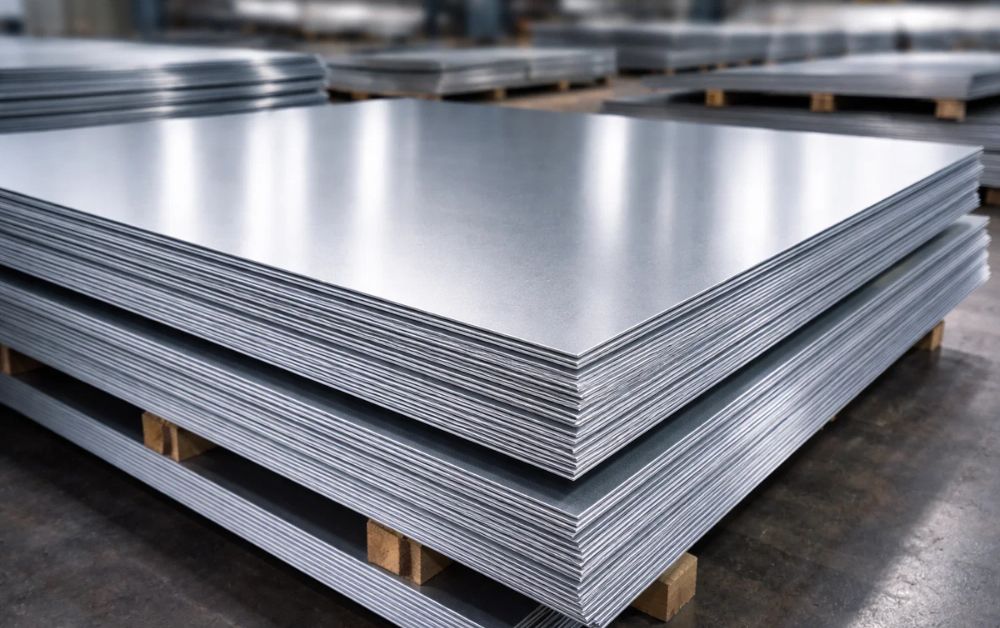

In the world of modern construction and manufacturing, galvanized Steel Coils play a vital role. Known for their corrosion resistance, durability, and cost-effectiveness, they are widely used across industries that demand long-lasting and high-performance materials. Produced by coating steel with a protective layer of zinc, galvanized coils provide a unique balance of strength and protection against environmental conditions.

Let’s dive into the top five applications of galvanized Steel Coils that are shaping industries worldwide.

1. Construction and Infrastructure

One of the most significant uses of galvanized Steel Coils is in the construction sector. From towering skyscrapers to residential housing projects, steel has always been the backbone of infrastructure.

Key Uses in Construction:

- Roofing and Cladding: Coils are processed into sheets for durable and weather-resistant roofing materials.

- Wall Panels and Frameworks: Used for strong structural frameworks that resist wear and tear.

- Bridges and Highways: Galvanized Steel Coils ensure longevity by resisting rust in outdoor structures exposed to extreme conditions.

The zinc coating protects against moisture and air, making the material ideal for structures that must withstand decades of exposure.

2. Automotive Industry

The automotive sector is another major consumer of galvanized Steel Coils. Vehicles require materials that are lightweight yet strong, and steel fulfills that need while also offering corrosion resistance.

Applications in Automobiles:

- Body Panels: Car hoods, roofs, and doors are often manufactured from galvanized steel for added safety and durability.

- Chassis and Frames: Provide the structural integrity needed to support vehicle weight.

- Exhaust Systems: Withstands high temperatures and exposure to moisture.

By using galvanized steel, manufacturers ensure vehicles have longer lifespans and reduced maintenance costs.

3. Appliances and Consumer Goods

Everyday household appliances also rely heavily on galvanized Steel Coils. From the kitchen to the laundry room, steel ensures products are both functional and durable.

Common Appliance Applications:

- Refrigerators and Washing Machines: Galvanized steel prevents rust in appliances that deal with constant exposure to water and moisture.

- Microwave Ovens and Dishwashers: Offer longevity and a clean finish.

- Air Conditioners and Heaters: Coils are processed into protective casings and internal components.

For consumers, this translates into appliances that last longer and maintain their quality even under heavy use.

4. Energy and Power Sector

The energy sector demands materials that can perform under extreme stress and weather conditions. Galvanized Steel Coils meet these requirements, making them ideal for projects in renewable energy, oil and gas, and power transmission.

Key Applications in Energy:

- Solar Panel Structures: Steel provides the base for solar panel mounting systems.

- Wind Turbines: Internal components rely on galvanized steel for strength and longevity.

- Transmission Towers: Galvanized coils are processed into beams and supports that withstand environmental stress.

By ensuring stability and reliability, steel plays an important role in sustainable energy solutions.

5. Industrial and Agricultural Equipment

Beyond construction and consumer goods, galvanized Steel Coils are widely used in heavy industries and agriculture. These sectors require tough materials that can handle constant use and outdoor exposure.

Examples of Use:

- Machinery: Frames and casings made from galvanized steel enhance durability.

- Storage Tanks and Silos: Used for storing water, grain, or chemicals due to corrosion resistance.

- Fencing and Agricultural Structures: Galvanized steel ensures farms and factories have long-lasting protective barriers.

Its adaptability makes it a trusted choice for sectors that rely on strength and performance in demanding environments.

Why Galvanized Steel Coils Are Preferred

Across all these industries, galvanized Steel Coils stand out due to:

- Corrosion Resistance: The zinc coating provides a protective barrier.

- Durability: Withstands heavy loads and environmental factors.

- Cost-Effectiveness: Offers long-term savings by reducing replacement and repair costs.

- Versatility: Can be cut, welded, and shaped to meet diverse needs.

These qualities make galvanized steel one of the most reliable materials in global supply chains.

Conclusion

Galvanized Steel Coils are far more than just raw materials — they are essential elements that power construction, automotive, energy, consumer goods, and agricultural sectors worldwide. Their ability to combine durability, affordability, and versatility makes them a top choice for industries seeking long-term reliability. For businesses and contractors looking for premium quality and trusted supply, one name that shines bright is SYDNEY METAL TRADING LLC, a reliable partner in delivering excellence in steel solutions.