Expanded metal mesh is one of those materials that is incredibly versatile, found everywhere from construction & architecture to industrial settings and security applications. Its strength, lightweight design, & ability to adapt to different needs make it a top option for many projects. But with so many options out there, how do you know which type of mesh is right for your specific needs? Let’s break down what you should consider when choosing metal mesh for your project.

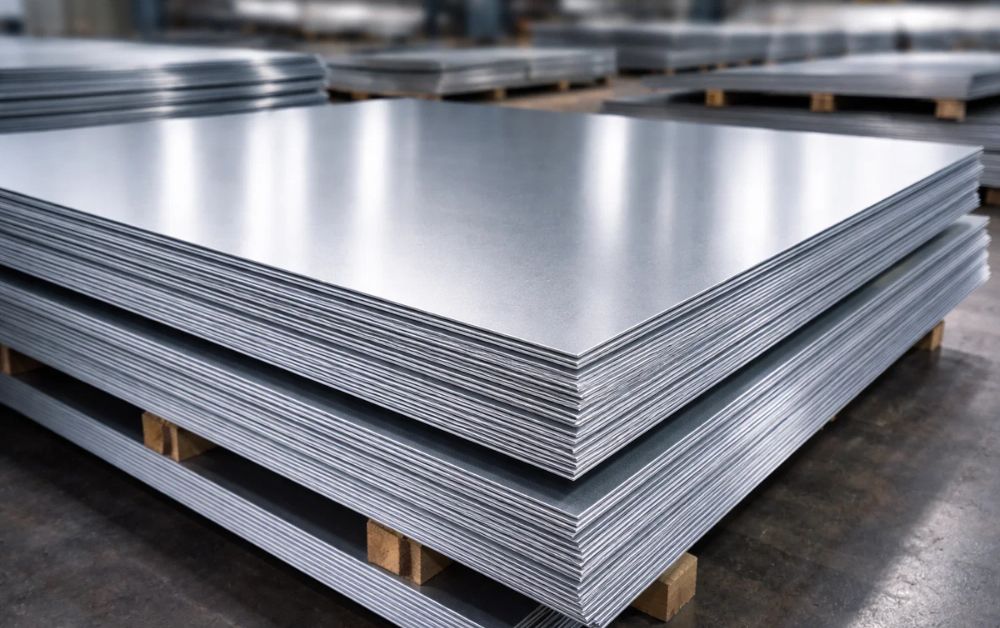

Think About the Material

The material you choose for your mesh is one of the most important decisions to make. Each type of metal comes with its own set of benefits, depending on the environment & what the mesh needs to do.

- Steel: Steel is strong and durable, making it a great option for heavy-duty applications like structural projects or industrial walkways.

- Stainless Steel: If your mesh is going to be exposed to moisture, chemicals, or harsh conditions, stainless steel is the way to go. It’s resistant to rust and corrosion, which makes it ideal for outdoor use.

- Aluminum: For projects where weight matters, aluminum is a great choice. It’s lightweight, rust-resistant, & works well for decorative features or lightweight enclosures.

Choosing the right material for the job ensures that your mesh holds up over time & performs the way you want it to.

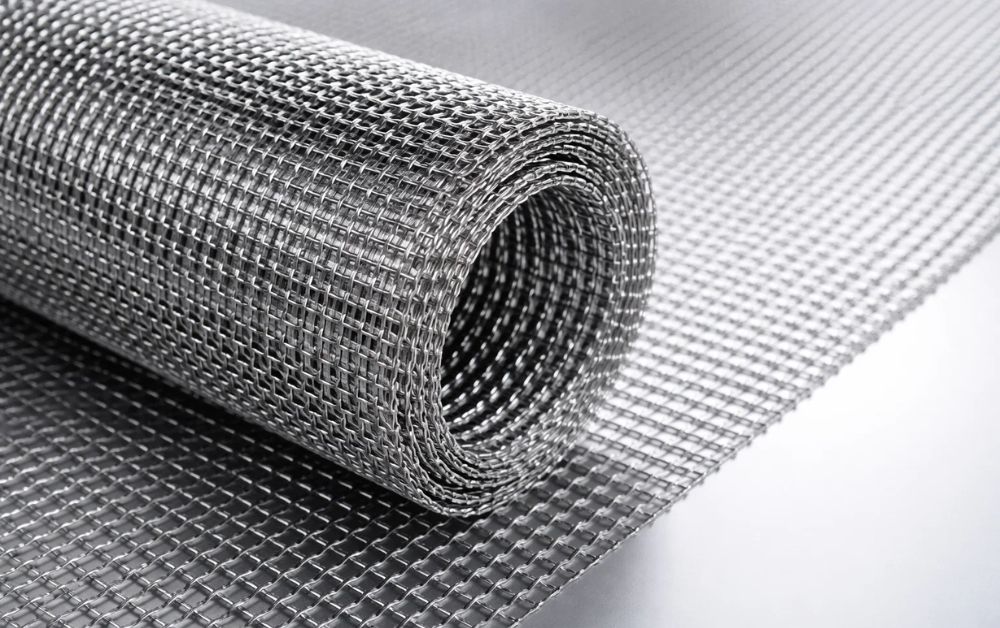

Mesh Size and Pattern Matter

The size of the openings and the pattern of the mesh affect both how it looks and how well it does its job. Consider how much airflow or visibility you need versus how much security or privacy.

- Opening Size: Larger openings provide more visibility & airflow, which is great for things like fencing or ventilation panels. But if you need security or privacy, smaller openings are a better choice.

- Strand Thickness: Thicker strands add strength but may limit how transparent or open the design feels. Thinner strands make the mesh lighter & more open, which can be useful for decorative purposes.

- Pattern: The diamond pattern is the most common because it’s strong and versatile. But if you’re working on something like an architectural feature, you might want to choose a more intricate pattern to add some visual interest.

It’s all about balancing form and function—so make sure the mesh pattern fits the job while still matching your design vision.

Strength and Load Capacity

If your mesh is going to bear weight or withstand impact, you will need to think about its strength. Not all metal mesh is created equal when it comes to load-bearing capacity, so you’ll need to choose one that can handle the demands of your project.

- Load-Bearing: Whether the mesh will be used for walkways, platforms, or barriers, make sure it can handle the load without bending or breaking.

- Impact Resistance: If you’re using the mesh in a security or industrial setting, you’ll want a thicker strand with smaller openings to resist impact.

- Durability: The right combination of material, strand thickness, & pattern will affect how durable the mesh is. Make sure these factors match the intended use to ensure the mesh lasts.

Always consider the mesh’s ability to withstand weight and impact to ensure it meets your project’s needs for safety & longevity.

Environmental Factors

The environment where the mesh will be used is a huge factor in deciding which type to go for. The mesh needs to be able to handle the conditions it will be exposed to.

- Outdoor Use: If the mesh is going to be exposed to rain, sun, or chemicals, you’ll need a material that can resist corrosion. Stainless steel and galvanized metals are great for these conditions.

- Indoor Use: For indoor use, things like appearance & ease of maintenance might be more important than extreme durability. Aluminum is often a good choice for these applications.

- Harsh Conditions: If you’re working in a coastal area with salty air or extreme temperatures, materials like aluminum and stainless steel are often best as they stand up to these tough conditions.

Understanding the environment where the mesh will be used ensures that it will hold up and perform as expected.

Compliance and Standards

Some projects, especially in construction or industrial settings, may require that the mesh meets specific safety standards or regulations.

- Building Codes: Make sure the mesh you choose meets local building codes, mainly if it’s being used in a structural application.

- Certifications: Look for materials that are certified (e.g., ISO or ASTM), which ensures they meet quality standards & perform as expected.

- Manufacturer Details: Always check technical datasheets for important information like load capacity, corrosion resistance, and other specs that matter for your project.

Compliance is key to making sure the mesh meets safety standards and lasts without issues down the road.

Cost and Availability

While performance is the priority, you also need to consider the cost and availability of the mesh you want.

- Initial Cost vs. Long-Term Value: Higher-quality materials or thicker strands may cost more upfront, but they could save you money in the long run by lasting longer and requiring less maintenance.

- Availability: Make sure the mesh you pick is available from suppliers and won’t cause delays in your project timeline.

- Supplier Reputation: Work with a trusted supplier who can deliver quality materials on time and offer support if you need it.

Balancing cost & quality is important to ensure you get the best value for your investment.

In Conclusion

Selecting the right expanded metal mesh isn’t just about picking any mesh that fits your budget—it’s about finding the material that matches the specific needs of your project. By considering things like material, pattern, strength, environmental factors, and cost, you will end up with a mesh that checks all the boxes. If you need expert guidance or high-quality mesh options, Sydney Metal Trading LLC is here to help you with everything from selection to installation.