In the world of modern manufacturing and construction, Cold Rolled Sheets have become one of the most essential materials due to their precision, durability, and smooth surface finish. These steel sheets undergo a specialized rolling process at room temperature, resulting in tighter tolerances, enhanced strength, and superior appearance. As industries continue to advance towards higher quality standards and sustainability, the demand for Cold Rolled Sheets is expected to grow significantly in 2026.

This article explores the various uses, benefits, and key selection tips for Cold Rolled Sheets—helping businesses and engineers make the right material choice for their upcoming projects.

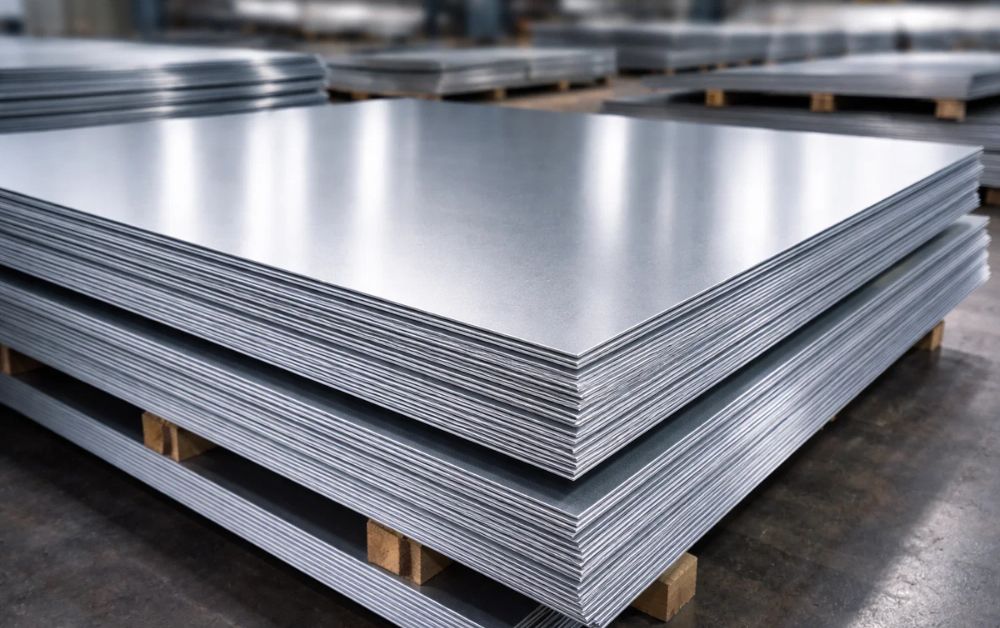

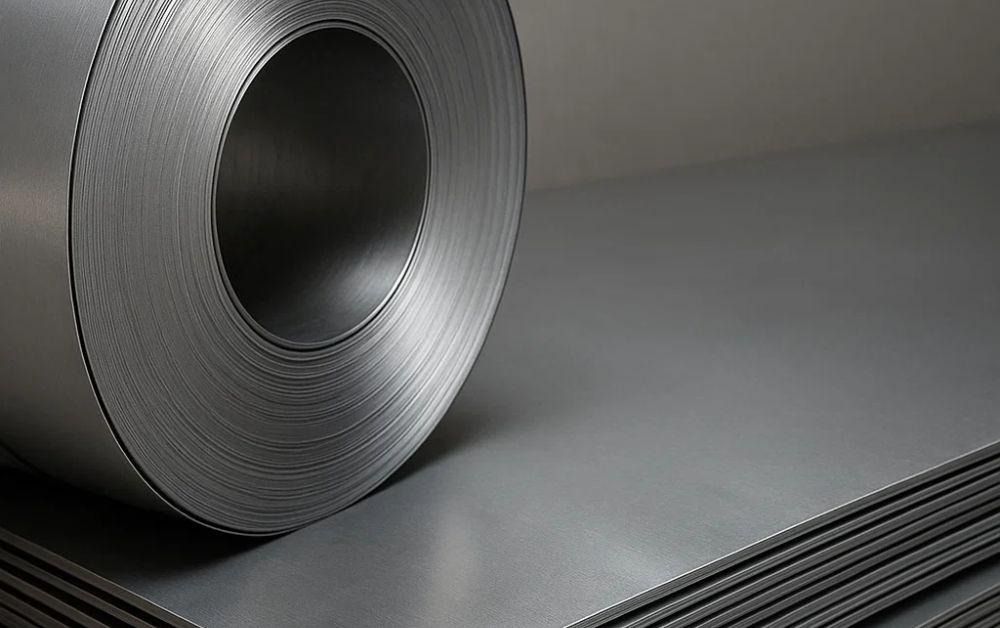

What Are Cold Rolled Sheets?

Cold Rolled Sheets are produced by taking hot rolled steel and further processing it at room temperature through a series of rollers. This process compresses the steel, improving its surface finish and dimensional accuracy. Unlike hot rolled steel, which tends to have rough surfaces and slightly uneven edges, cold rolled variants are smooth, uniform, and precisely sized.

The cold rolling process also increases the steel’s strength and hardness through strain hardening, making it an excellent choice for applications where precision and surface quality are crucial.

Common Uses of Cold Rolled Sheets

The versatility of Cold Rolled Sheets allows them to serve a wide range of industries. Their refined surface finish, durability, and tight dimensional control make them a preferred material for various applications.

1. Automotive Industry

One of the largest consumers of Cold Rolled Sheets is the automotive sector. These sheets are used in body panels, frames, doors, and roofs because of their excellent formability and surface finish. Their ability to resist wear and deformation under stress makes them ideal for modern vehicle design.

2. Home Appliances

Household products like refrigerators, washing machines, ovens, and air conditioners often use Cold Rolled Sheets due to their aesthetic appeal and corrosion resistance. Their smooth surface allows easy painting and coating, giving appliances a polished and durable finish.

3. Construction and Architecture

In construction, these sheets are used for roofing, wall cladding, interior partitions, and ceilings. Their uniform thickness and strength help builders maintain structural stability while achieving a clean, modern look.

4. Furniture and Fixtures

Modern office furniture, shelving units, and cabinets often use Cold Rolled Sheets for their clean lines, lightweight nature, and long-lasting performance. They can be easily fabricated into customized designs that combine style and functionality.

5. Electrical and Industrial Equipment

Electrical panels, switchboards, enclosures, and precision tools are commonly made from cold rolled steel. The sheets’ dimensional accuracy ensures tight-fitting components and high-quality assembly.

Key Benefits of Cold Rolled Sheets

Choosing Cold Rolled Sheets offers several advantages compared to other steel materials. These benefits have positioned them as a top choice for industries that prioritize precision, durability, and aesthetics.

1. Superior Surface Finish

The cold rolling process produces a smooth and bright surface free from scale or rough textures. This makes the sheets ideal for applications that require painting, coating, or decorative finishes.

2. High Dimensional Accuracy

Cold Rolled Sheets are manufactured with extremely tight tolerances, ensuring consistent thickness and flatness. This precision helps in achieving perfect fitting components and seamless assemblies.

3. Enhanced Mechanical Strength

Due to strain hardening during processing, these sheets are stronger and more durable than hot rolled steel. This makes them suitable for structural applications that demand rigidity and endurance.

4. Easy to Form and Fabricate

Despite their strength, Cold Rolled Sheets maintain excellent formability. They can be bent, cut, welded, and shaped into complex designs without compromising their integrity.

5. Better Corrosion Resistance

When combined with coatings or galvanization, Cold Rolled Sheets provide exceptional resistance against rust and environmental damage, ensuring a longer service life.

6. Energy Efficiency and Sustainability

Modern steel manufacturers use energy-efficient processes to produce Cold Rolled Sheets, reducing waste and carbon emissions. Their recyclability further supports sustainable manufacturing goals for 2026 and beyond.

Selection Tips for 2026: Choosing the Right Cold Rolled Sheets

As technology and sustainability requirements evolve, selecting the right Cold Rolled Sheets involves more than just considering size or thickness. Below are some key tips to help industries make informed decisions:

1. Identify Your Application Needs

Determine whether the sheets will be used for structural support, surface finishing, or high-strength components. This will help you choose the appropriate grade and coating type.

2. Consider Mechanical Properties

Check the yield strength, tensile strength, and ductility of the steel. For example, automotive applications may require higher strength grades, while furniture fabrication might prioritize flexibility and smoothness.

3. Inspect Surface Quality

Ensure the surface finish meets your aesthetic or coating requirements. Sheets with minimal imperfections are best for decorative or visible components.

4. Look for Certified Suppliers

Only purchase from suppliers that comply with international quality standards such as ASTM, ISO, or EN certifications. This guarantees consistency and reliability in material performance.

5. Evaluate Cost vs. Performance

While Cold Rolled Sheets might cost slightly more than hot rolled alternatives, their durability and precision often result in lower long-term maintenance and production costs.

6. Sustainability and Recycling Considerations

As 2026 approaches, industries are shifting towards eco-friendly materials. Ensure your supplier sources and manufactures steel sheets responsibly, emphasizing energy efficiency and recyclability.

Conclusion

In 2026 and beyond, Cold Rolled Sheets will continue to play a central role in industries that demand precision, performance, and sustainability. From automotive manufacturing to construction and home appliances, their superior finish, strength, and reliability make them indispensable.

For businesses looking for high-quality and certified Cold Rolled Sheets in the UAE, Sydney Metal Trading LLC stands out as a trusted name. Renowned for its commitment to quality, timely delivery, and customer satisfaction, the company offers a comprehensive range of steel products designed to meet evolving industrial needs. Whether you’re building, fabricating, or innovating — Sydney Metal Trading LLC ensures excellence and durability in every sheet supplied.