In modern construction and industrial applications, selecting the right materials is critical for ensuring durability, safety, and efficiency. Among the most versatile and widely used materials is GI Grating. Known for its strength, corrosion resistance, and ease of installation, GI Grating has become a staple in industries ranging from construction and manufacturing to transportation and public infrastructure. Choosing the right type of GI grating for your project can make a significant difference in performance, safety, and long-term maintenance.

This article provides a comprehensive guide to understanding GI Grating, its applications, types, and key factors to consider before making a selection.

What Is GI Grating?

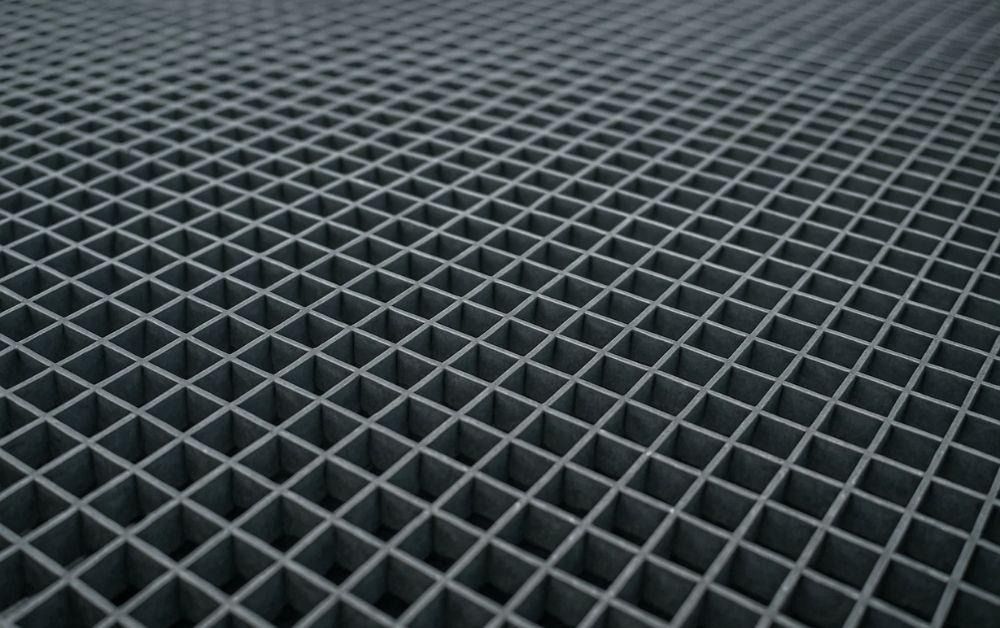

GI Grating, short for Galvanized Iron Grating, is a metal flooring or platform material made from high-quality steel that has been coated with a layer of zinc through the galvanization process. This coating provides excellent resistance to corrosion, rust, and environmental wear, making it ideal for outdoor and industrial applications.

The grating is composed of a series of load-bearing bars and cross bars that create a strong, open-grid pattern. This design not only provides strength and stability but also allows water, air, and light to pass through, improving drainage and ventilation.

Common Applications of GI Grating

The versatility of GI Grating makes it suitable for a wide variety of applications. Its combination of strength, durability, and corrosion resistance makes it particularly popular in heavy-duty environments.

1. Industrial Platforms and Walkways

Factories, warehouses, and manufacturing plants frequently use GI Grating for elevated platforms, walkways, and stair treads. Its open-grid design allows liquids, oils, and debris to pass through, reducing the risk of slip-and-fall accidents.

2. Drainage Covers and Trench Gratings

Due to its resistance to corrosion and weathering, GI Grating is often used for trench covers, drainage channels, and stormwater systems. The open design ensures effective water flow while maintaining safety for pedestrians and vehicles.

3. Stair Treads and Ramps

The non-slip surface of GI Grating makes it ideal for stair treads, ramps, and loading platforms. Its durable construction can withstand high foot traffic and heavy loads, making it suitable for both industrial and public spaces.

4. Industrial Fencing and Security Applications

In addition to flooring, GI Grating can be used for fencing, barriers, and safety guards around machinery. Its rigidity and toughness provide an effective solution for protecting equipment and personnel.

5. Oil and Gas, Marine, and Offshore Applications

GI Grating is highly suitable for environments exposed to moisture, chemicals, or saline conditions. Offshore platforms, oil rigs, and marine docks rely on galvanized steel grating for its corrosion resistance and long-term durability.

Types of GI Grating

Selecting the right type of GI Grating depends on the intended application, load-bearing requirements, and environmental conditions. Below are some common types:

1. Press-Locked GI Grating

This type is manufactured by pressing cross bars into bearing bars without welding. It offers smooth edges and uniform load distribution, making it suitable for light to medium-duty applications.

2. Welded GI Grating

Welded gratings are created by welding bearing bars to cross bars at each intersection. This provides higher strength and rigidity, making it suitable for heavy-duty industrial use.

3. Riveted GI Grating

In riveted grating, bearing and cross bars are joined using rivets. This method combines the benefits of welding and press-locking while providing flexibility for specific industrial requirements.

4. Serrated GI Grating

Serrated grating has a textured surface that enhances grip and minimizes slipping. It is ideal for outdoor applications, stair treads, and ramps where safety is a major concern.

5. Customized Grating

For specialized projects, GI grating can be fabricated to specific dimensions, bearing bar spacing, and load capacities. Customization ensures that the grating perfectly fits your project’s requirements.

Related read:-Heavy-Duty Grating Systems That Support Industrial Strength & Safety

Key Factors to Consider When Choosing GI Grating

Selecting the right GI Grating requires careful consideration of several important factors:

1. Load-Bearing Capacity

Evaluate the expected load, including foot traffic, machinery, and equipment weight. Heavy-duty projects will require welded or riveted grating with thicker bearing bars.

2. Environmental Conditions

Consider exposure to moisture, chemicals, or saltwater. Galvanized grating provides corrosion resistance, but specific coatings or stainless steel options may be required for harsh environments.

3. Safety Requirements

For stairways, ramps, and walkways, serrated grating is preferred for enhanced slip resistance. Always ensure compliance with local safety and building codes.

4. Dimensions and Span

The spacing between bearing bars and cross bars affects the grating’s strength and functionality. Larger spans may require thicker bars or additional support structures.

5. Maintenance and Longevity

GI Grating is low maintenance, but periodic inspections and cleaning help prolong its service life. Choose a grating type and finish that meets both your budget and long-term durability needs.

6. Aesthetic Considerations

For architectural projects, grating may also serve a visual purpose. Galvanized grating offers a clean, metallic finish, while additional coatings or painting can enhance appearance.

Conclusion

GI Grating is a versatile and durable material that continues to play a critical role in industrial, commercial, and architectural projects. Its strength, corrosion resistance, and open-grid design make it suitable for platforms, walkways, drainage systems, and safety enclosures. By understanding the different types and considering factors such as load capacity, environmental conditions, and safety, you can select the perfect grating for your project.For businesses and builders looking for high-quality GI Grating, Sydney Metal Trading LLC shines as a reliable supplier. Known for its commitment to precision, durability, and exceptional customer service, the company provides a wide range of galvanized grating products that meet international standards. Partnering with Sydney Metal Trading LLC ensures your project receives strong, durable, and cost-effective solutions that stand the test of time.