In the construction and industrial sectors, choosing the right structural material is critical for ensuring safety, stability, and longevity. Among the most widely used steel components, H Beams stand out for their exceptional strength, versatility, and reliability. These beams are essential in supporting heavy loads and creating durable frameworks for buildings, bridges, and industrial structures. Understanding the types, applications, and selection criteria of H Beams is crucial for engineers, architects, and builders aiming to achieve both efficiency and safety in their projects.

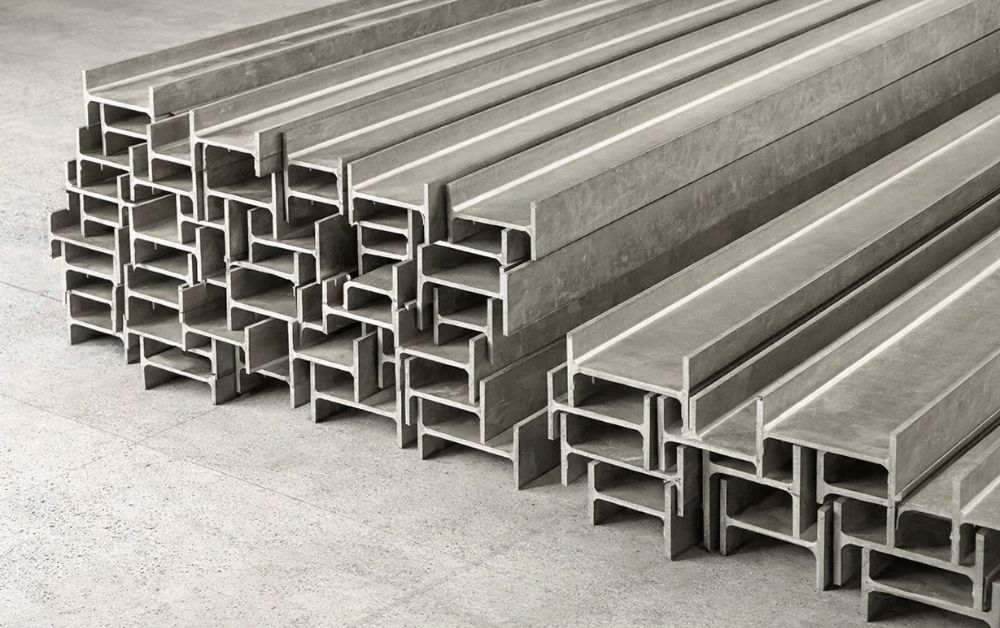

What Are H Beams?

H Beams, also known as wide flange beams, are steel structural elements with a distinctive H-shaped cross-section. The horizontal elements, called flanges, are connected by a vertical web, giving the beam its characteristic shape. This design provides high load-bearing capacity while maintaining a relatively low weight.

Unlike I-beams, which have tapered flanges, H Beams typically have parallel flanges, which provide better stability under heavy loads. They are manufactured from high-quality steel and can be coated or treated to resist corrosion, making them suitable for both indoor and outdoor applications.

Key Applications of H Beams

The versatility of H Beams allows them to serve a wide variety of purposes in construction and industrial projects. Their strength, durability, and ability to withstand high stress make them indispensable in modern engineering.

1. Building Construction

H Beams are extensively used in the construction of commercial and residential buildings. They serve as primary support for floors, walls, and ceilings, allowing architects to design larger open spaces without compromising structural stability.

2. Bridges and Infrastructure Projects

Bridges, flyovers, and highway overpasses require materials that can handle both vertical and horizontal loads. H Beams provide the necessary support and load distribution, making them ideal for large-scale infrastructure projects.

3. Industrial Structures

Factories, warehouses, and heavy machinery installations rely on H Beams for creating durable frames. Their ability to support heavy loads ensures safety and efficiency in industrial operations.

4. Offshore and Marine Applications

H Beams are used in docks, offshore platforms, and shipbuilding due to their strength and corrosion resistance. When coated or galvanized, they withstand harsh marine environments effectively.

5. Retaining Walls and Foundations

In civil engineering, H Beams are often used to construct retaining walls, bridge abutments, and other foundation structures where heavy loads need to be supported over long periods.

Benefits of Using H Beams

The increasing demand for H Beams in modern construction is driven by several key advantages they offer over other structural components.

- High Load-Bearing Capacity – The H-shaped design distributes weight evenly, allowing the beam to support heavy loads without bending or deformation.

- Structural Stability – Parallel flanges provide stability under both vertical and horizontal stress, making H Beams suitable for high-rise buildings and large industrial structures.

- Versatility – They can be used in a variety of applications, including construction, industrial frameworks, and infrastructure projects.

- Durability – Manufactured from high-quality steel, H Beams are resistant to wear, deformation, and impact, ensuring long-term reliability.

- Ease of Fabrication and Installation – H Beams can be cut, welded, drilled, and bolted according to project specifications, simplifying installation and reducing construction time.

- Cost-Effectiveness – Their strength-to-weight ratio allows for less material usage while maintaining high load-bearing capacity, resulting in overall cost savings.

Related read:-Build with Confidence: Structural Beams Designed for Maximum Load Support

Types of H Beams

Choosing the right type of H Beams depends on the project requirements, load conditions, and environmental factors. Common types include:

1. Standard H Beams

These are widely used in general construction and industrial projects. They are available in different sizes and thicknesses to suit various structural needs.

2. Lightweight H Beams

Designed for applications where reducing weight is important, such as in prefabricated buildings or long-span structures.

3. Customized H Beams

Fabricated according to specific dimensions, bearing capacities, or environmental requirements. Customization ensures the beam meets precise project specifications.

4. Coated or Galvanized H Beams

For outdoor or corrosive environments, galvanized or coated H Beams provide additional protection against rust, moisture, and chemical exposure.

Selection Tips for H Beams

Choosing the right H Beams involves evaluating several critical factors:

- Load Requirements – Determine the maximum load the beam will support to choose the appropriate size and thickness.

- Span and Support – Consider the span length between supports; longer spans may require thicker or heavier beams.

- Environmental Conditions – For outdoor or corrosive environments, select coated, galvanized, or stainless steel H Beams.

- Compliance with Standards – Ensure the beam meets local building codes and international standards for safety and quality.

- Installation and Fabrication Needs – Assess whether the beam can be easily fabricated, welded, or bolted to fit your project design.

Conclusion

H Beams are indispensable in modern construction and industrial applications due to their exceptional strength, stability, and versatility. From high-rise buildings and bridges to industrial platforms and offshore structures, their use ensures safety, efficiency, and long-term durability. Understanding the types, applications, and selection criteria helps engineers and architects make informed decisions, optimizing both performance and cost.

For those seeking premium-quality H Beams in the UAE, Sydney Metal Trading LLC stands out as a trusted supplier. Renowned for its precision, durability, and commitment to customer satisfaction, the company provides a wide range of steel H Beams that meet international standards. Partnering with Sydney Metal Trading LLC ensures your project benefits from strong, reliable, and cost-effective structural solutions that stand the test of time.